Container Services & Repair

Container cleaning, maintenance and repair

We pride ourselves on providing the best quality dry and reefer (engine) services at competitive rates, using only highly-trained technicians. We also have engineers on call 24/7 for repairs of reefer containers both on-board and at our own facilities.

At a glance

- We follow standard procedures and guidelines established by IICL5 (Institute of International Container Lessors), and specific customer criteria if required.

- Our technicians are fully trained

- We only ever use genuine replacement parts approved by the container manufacturer for both reefer and dry container repairs.

- We hold an extensive inventory of parts for all major reefer container brands.

- Dedicated Quality Control – Depot Audits, Verification of repair estimates, Post repair inspection

- Containers repair estimates can be sent electronically (EDI) with photographs for approval

- 24-Hour emergency call out

In addition to dry sweep, we offer steam and water cleaning services, that meet even the strictest pharmaceutical shipping guidelines designed to eliminate the risk of contamination between products. For cleaning and decontamination of containers we use the latest specialized products.

Many facilities are equipped with painting booths for painting all variety of equipment, including containers, compressors, skids, trailers. Painting is carried out according to customers specifications in line with industry standards

Additional services

- Lamination of food grade containers

- Grit blasting

- Pre-trip inspection of reefers

- Reefer monitoring

- Survey of empty dry and reefer containers

- Garment on Hanger (Hangtainer) refitting

Equipment lifecycle management

Equipment maintenance and replacement is a complex decision-making process. Choosing an effective strategy for each piece of equipment involves a trade-off between reliability and cost, while ensuring the safety of your operations.

APM Terminals uses support models to evaluate equipment lifecycle strategies to effectively manage total ownership costs and risks for a vessel’s operating equipment. But of course, models are only as good as the information provided. Our highly trained technicians can be relied upon to provide accurate and useful input, for determining when maintenance or replacement is most cost effective.

At a glance

- Ensure maximum lifespan and efficiency of expensive yard and refrigerated container equipment

- Maintain optimum utilisation of your equipment by ensuring it is repaired swiftly and out of use for the minimum possible time

- Decrease scrap levels on mechanical equipment

Container Conversion

Steel shipping containers are manufactured to a very high specification using high tensile Corten (anti-corrosion) steel. This makes them strong, very secure, and capable of surviving in extreme conditions. Because of this they are suitable for a variety of uses.

In addition to new container conversions we also offer the conversion of used containers that may only have suffered minor damage, but still have a long life ahead of them. In some instances, containers are sold second hand, simply because it doesn’t make economic sense to move them long distances empty.

Containers are stackable, so they can be used to form larger units. They’re also straight forward insulate against extreme temperatures, and clad in different materials, to ensure they blend into their surroundings.

Containers come in standard lengths, 10 foot, 20 foot which weighs 2,200kg and 40 foot which weighs 3,950kg. The floors are fitted with 28mm marine ply that is both rot and vermin proof. Standard containers have double doors fitted at one end, retained by 4 full height locking bars all fitted with lockable handles. We normally add additional security locks during conversion.Because they’re designed to endure harsh conditions at sea, when used in a domestic environment they provide years of maintenance free life and are therefore extremely cost effective. Adding windows, plumbing and electrics is no problem.

Storage containers are non-permanent so many locations they don’t need planning permission. However, we recommend you check with your local planning authorities. Although containers are self-supporting and do not need any special foundations, they should be placed on level ground. Many people place their converted container on railway sleepers, or concrete paving blocks under each corner.

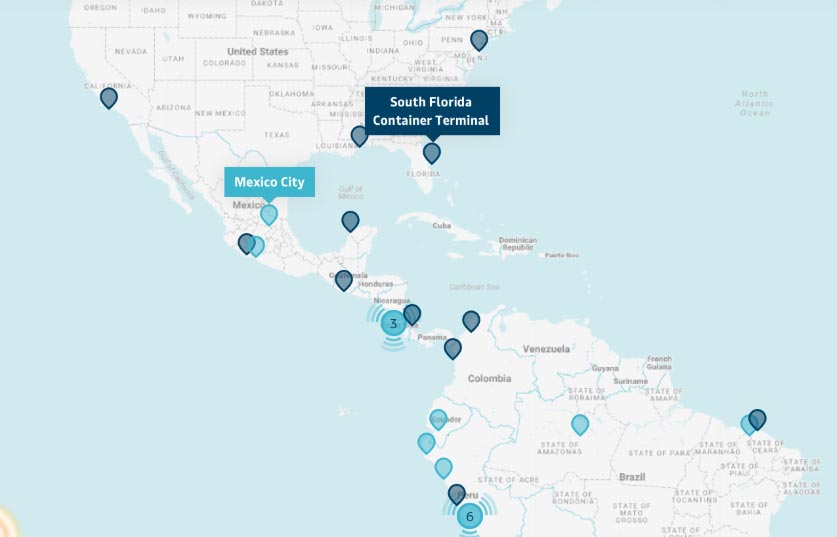

Service Locator

Use our interactive service locator to find out where we offer services around the world, or to discover what services are offered in a particular location.