Reefer Services

Reefer containers are just one part of a complete Cold Chain Solution offered by APM Terminals. By working with our customers to optimise their cold chain, we add real value to their business.

In addition to the traditional services outlined below, we are happy to discuss your complete cold chain requirements. In response to demand in certain markets we offer solutions that can maintain humidity and temperatures for fruits and vegetables, such as temperature controlled docks, temperature controlled areas for packing, facilities for blast freezing and chillers.

We appreciate the value of your reefer cargo and therefore ensure that our facilities are equipped with reliable power sources, 24-hour back up, and the latest in digital data logging. Our terminals and storage depots use the latest technology such as CCTV and controlled access to ensure the highest levels of security.

National & International Certification

In addition to complying with local and international laws for food safety, many of our facilities are certified according to international guidelines for handling organic produce. To comply with local and international standards, where required, we also offer facilities and the latest equipment for phytosanitary inspections.

Reefer Storage

Our terminals are equipped with adequate reefer plugs and racking to handle all reefer storage requirement, even in today’s rapidly growing reefer market. We’re continually investing in all of our terminals according to detailed forecasts to ensure we continue to meet market demand at an affordable price. Almost all of our facilities offer bonded reefer storage both on and off-dock, to minimise customs administration.

Pre-trip Inspection (PTI)

APM Terminals carries out PTIs according to the strict guidelines provided by shipping lines. We carry out PTI for all shipping lines.

Shipping lines will not release a container before a PTI has been carried out as this could potentially lead to a claim. The PTI is conducted on an empty reefer container to ensure the correct functioning of the cooling unit, temperature control and recording devices. This includes a detailed inspection of bolts, compressor mountings, connectors, hoses, cable condition, insulation and more. PTI also includes checking the container for structural damage, and ensuring that the inside of the container is clean and ready to receive cargo.

During the PTI the temperature, humidity and ventilation will also be set according to the customers specification.

Pre-Cooling

Pre-trip inspections should not be confused with pre-cooling, which involves pre-cooling products (wherever required) to the required carriage temperature before being packed into the container. We provide this at our cold-storage facilities or directly at the customer in the container, if necessary. This improves the shelf life of the cargo.

Reefer Monitoring & Setting Adjustment

Our Terminals and Inland Depots are well equipped to handle all types of conditioned cargo, particularly refrigerated containers. We will always ensure we have sufficient reefer connections to meet requirements and a stable power supply. Many of our terminals have recently increased reefer capacity and improved electricity infrastructure to meet growing global demand. We also have a preference for electricity from renewable sources wherever possible.

Depending on the technology used, we provide both 24/7 physical and remote reefer monitoring for container in our care. Our technicians are familiar with all remote monitoring systems in use. These provide regular updates on power status, and temperature and atmospheric conditions inside the container. Technicians are able to adjust these if required, or in case of failure, to immediately send a technician, day and night. We can also adjust conditions inside the container in accordance with customer’s requirements, to allow for example, for gradual temperature increases. We can also provide container history, to check conditions inside the container retrospectively.

Genset Mounting

Our technicians receive ongoing training to ensure that they have a good understanding of even the latest technologies for all major brands including Carrier, Daikin and Thermoking. Many have years of experience, with both clip-on gensets and underslung gensets, either mounted to the chassis of the container on the bottom side or attached to the frame of the truck, so that the genset doesn’t have to be demounted when another container is loaded on the truck. At many of our facilities we also lease, sell and repair gensets.

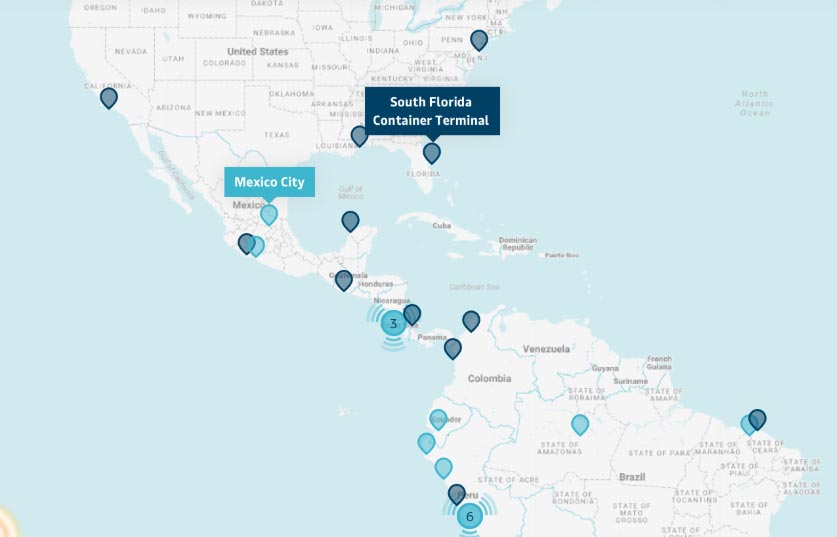

Service Locator

Use our interactive service locator to find out where we offer services around the world, or to discover what services are offered in a particular location.