05/06/24

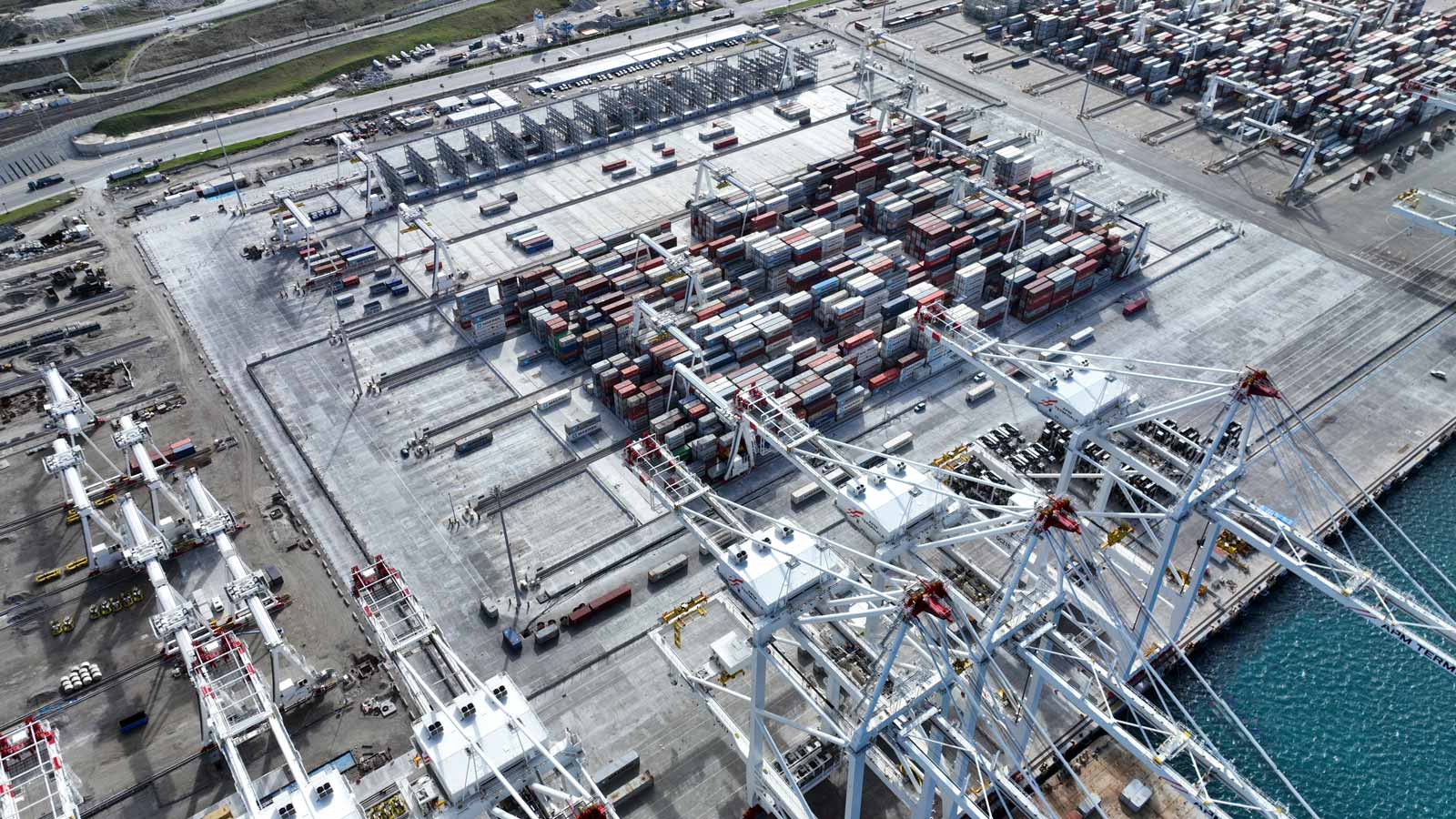

APM Terminals ramps up capacity with agreements for 240 pieces of container handling equipment

- APM Terminals continues its growth strategy with large investments in terminal equipment.

- Investment in 240 pieces of new equipment we agreed over the past months to meet the needs of expansions at APM Terminals Maasvlakte II, APM Terminals MedPort Tangier, Côte d’Ivoire Terminal, APM Terminals Lazaro Cardenas, Suez Canal Container Terminal and the upcoming terminal in Suape, Brazil.

APM Terminals has made milestone investments for five of its terminals in Latin America, Africa and Europe to be ready to serve the customers of the future. Investing in 240 new pieces of terminal equipment, from ship-to-shore cranes to rubber tyred gantry cranes and electric terminal tractors, APM Terminals is set to lift standards of operational excellence.

“To serve our customer's needs and realise our growth strategy for APM Terminals, we are ramping up our capacity with cutting-edge products and technology. The agreements we have signed with ZPMC, Sany, Kuenz, Shacman and ABB will help us drive efficiency and sustainability in our operations,” says Olaf Gelhausen, COO APM Terminals.

Crane manufacturer ZPMC will deliver 12 ship-to-shore cranes to APM Terminals Maasvlakte II in the Netherlands, 4 ship-to-shore cranes for APM Terminals MedPort Tangier in Morocco, 2 ship-to-shore cranes and 9 rubber-tyred-gantry cranes for Côte d’Ivoire Terminal (CIT), 6 automated rail mounted gantry cranes and 14, 1-over-1 hybrid straddle carriers for APM Terminals Lazaro in Mexico. The agreement, signed on April 18 in the Hague, celebrates a two-decade long partnership between the two parties on advanced terminal equipment.

“We continue to uphold the principles of openness and trust and to engage in joint Kaizens to collectively enhance the entire project delivery process. This will enable us to reduce lead times and optimize the supply chain of spare parts,” says ZPMC Chairman Mr. You Ruikai.

100% electric equipment for Suape, Brazil

Future equipment for the upcoming terminal in Suape, Brazil is also now secured, as APM Terminals and Sany officially put pen to paper on April 25 in The Hague. Here the companies also signed a global framework agreement for port cranes. Sany will deliver 2 remotely operated ship-to-shore cranes, 7 remote controlled rubber tyred gantry cranes, 2 electric reach stackers, 2 electric empty container handlers, 1 electric forklift and 14 electric terminal tractors for APM Terminals Suape.

“In Suape, we are developing a state-of-the-art facility with great connectivity for the Brazilian northeast region. Being the first 100% electric terminal in Latin America, our goal is to provide safe, competitive and environmentally friendly solutions that will generate an outstanding experience for local customers,” explains Olaf Gelhausen of APM Terminals.

“We are very happy to provide the terminal in Suape with electric equipment in line with the global strategy for APM Terminals to electrify and decarbonise operations. The Sany team stands ready to support APM Terminals to reach the goals of the future to provide sustainable, operational excellence,” says Mr. Jeff Fu, CEO of Sany Marine.

The terminal in Brazil will be the first 100% electric terminal in Latin America and will be ready to operate in 2026.

Milestone investments

The new investment agreements add to the list of good news from APM Terminals this spring. In March the company announced plans with Kuenz and ABB to provide 62 automated rail mounted gantry cranes and 1 intermodal yard crane for the expansion of Maasvlakte II. The agreement marked APM Terminals’ largest crane order in Europe to date and will help double capacity in the terminal by 2027.

During March, the Suez Canal Container Terminal also signed a deal for the supply of 90 terminal tractors from Shacman; and 5 empty container handlers, 4 reach stackers, 3 forklifts from Sany to support the expansion of the terminal and to continue serving customers in the terminal that currently has an annual throughput of 4 million TEUs and will expand by a further 2 million TEUs in the future.

Facts

- 12 Ship-to-shore cranes will be provided for Maasvlakte II as well as 62 automated rail mounted gantry cranes and 1 intermodal yard crane

- 4 Ship-to-shore cranes will be provided for APM Terminals MedPort Tangier

- 2 Ship-to-shore cranes and 9 rubber tyred gantry cranes for Côte d’Ivoire Terminal (CIT).

- For Suape, 2 remote operated ship-to-shore cranes, 7 remote controlled rubber tyred gantry cranes, 2 electric reach stackers, 2 electric empty container handlers, 1 electric forklift and 14 electric terminal tractors will be provided.

- 6 Automated rail mounted gantry cranes and 14 straddle carriers for APM Terminals Lazaro Cardenas.

- 90 terminal tractors, 4 reach stackers, 5 empty container handlers, 3 forklifts for Suez Canal Container Terminal (SCCT)